Land Rover Discovery: Anti-lock Control - Operation

ANTI-LOCK BRAKE SYSTEM (ABS)

The Anti-lock Brake System (ABS) controls the speed of all road wheels to ensure optimum wheel slip when braking at the adhesion limit. The wheels are prevented from locking to retain effective steering control of the vehicle.

The front and rear brake pressures are modulated separately for each wheel.

CORNER BRAKE CONTROL (CBC)

Corner Brake Control (CBC) influences the brake pressures, below and within ABS thresholds, to counteract the yawing moment produced when braking in a corner. CBC produces a correction torque by limiting the brake pressure on one side of the vehicle, to assist the vehicle in achieving the turn radius the driver is requesting.

DYNAMIC STABILITY CONTROL (DSC)

Dynamic Stability Control (DSC) uses brakes and powertrain torque control to assist in maintaining the lateral stability of the vehicle. While the ignition is energized the DSC function is permanently enabled, unless selected off using the DSC switch.

DSC enhances driving safety in abrupt maneuvers and in under-steer or over-steer situations that may occur in a bend. The ABS control module monitors the yaw rate and lateral acceleration of the vehicle and the steering input, then selectively applies individual brakes and signals for powertrain torque adjustments to reduce under-steer or over-steer.

In general:

- In an under-steer situation; the inner wheels are braked to counteract the yaw movement towards the outer edge of the bend.

- In an over-steer situation; the outer wheels are braked to prevent the rear end of the vehicle from pushing towards the outer edge of the bend.

The ABS control module monitors the tracking stability of the vehicle using inputs from the wheel speed sensors, the steering angle sensor, and the yaw rate sensor. The tracking stability is compared with stored target data.

Whenever the tracking stability deviates from the target data, the ABS control module intervenes by applying the appropriate brakes.

The following interactions occur in an intervention situation:

- High speed (HS) Controller Area Network (CAN) chassis signal to the Engine Control Module (ECM), to reduce engine torque.

- HS CAN chassis bus signal to the Rear Differential Control Module (RDCM), to open the locking torque of the center coupling. - If required

- Application of braking to the appropriate corner of the vehicle.

ELECTRONIC BRAKE FORCE DISTRIBUTION (EBD)

Only the rear brakes are controlled by the Electronic Brake Force Distribution (EBD) function. EBD limits the brake pressure applied to the rear wheels. When the brakes are applied, the weight of the vehicle transfers forwards, reducing the ability of the rear wheels to transfer braking effort to the road surface. This may cause the rear wheels to slip and make the vehicle unstable.

EBD uses the Anti-lock brake System (ABS) hardware to automatically optimize the pressure of the rear brakes, below the point where ABS is normally invoked.

ELECTRONIC TRACTION CONTROL (ETC)

Electronic Traction Control (ETC) attempts to optimize forward traction by reducing engine torque, or by applying the brake of a spinning wheel until traction is regained.

ETC is activated if an individual wheel speed is above that of the vehicle reference speed (positive slip) and the brake pedal is not pressed. The brake is applied to the spinning wheel, allowing the excess torque to be transmitted to the non-spinning wheels through the drive line. If necessary, the ABS control module also sends a High Speed (HS) Controller Area Network (CAN) chassis bus message to the ECM to request a reduction in engine torque.

When the Dynamic Stability Control (DSC) function is selected off using the DSC switch, the engine torque reduction feature is disabled.

EMERGENCY BRAKE ASSIST (EBA)

Emergency Brake Assist (EBA) helps the driver in emergency braking situations by automatically maximizing the applied braking effort. There are two situations when the ABS control module will invoke EBA:

- When the brake pedal is rapidly pressed.

- When the brake pedal is pressed hard enough to bring the front brakes into ABS operation.

When the brake pedal is rapidly pressed, the ABS control module increases the hydraulic pressure to all of the brakes until the threshold for ABS operation is reached. This action applies the maximum braking effort for the available traction. The ABS control module monitors for the sudden application of the brakes using inputs from the brake pedal switch and from the pressure sensor within the Hydraulic Control Unit (HCU). With the brake pedal pressed, if the rate of increase of hydraulic pressure exceeds the predetermined limit, the ABS control module invokes emergency braking.

When the brake pedal is pressed hard enough to bring the front brakes into ABS operation, the ABS control module increases the hydraulic pressure to the rear brakes up to the ABS threshold.

EBA operation continues until the driver releases the brake pedal sufficiently for the hydraulic pressure in the HCU to drop below a threshold value stored in the ABS control module.

INTELLIGENT EMERGENCY BRAKING (IEB)

Intelligent Emergency Braking (IEB) reduces the impact velocity if the Adaptive Speed Control Module (ASCM) determines that a collision is

unavoidable, even with driver intervention. It is not designed to prevent accidents from occurring. Typical activation of intelligent emergency braking is approximately 0.8 second before impact. During this 0.8 second period the speed of the sensing vehicle is reduced, thus reducing the impact energy.

If the ASCM determines a collision is unavoidable, it signals the Anti-lock Brake System (ABS) control module to apply emergency brake pressure to all of the brakes. On vehicles without active safety belts, emergency brake pressure is 50bar (725lbf/in²) maximum. On vehicles with active safety belts, emergency brake pressure is 100bar (1450lbf/in²) maximum.

When intelligent emergency braking is initiated the ASCM also signals the Restraints Control Module (RCM) to fire the front seatbelt retractors.

For additional information, refer to: Seatbelt System (501-20A Seatbelt System, Description and Operation).

After the intelligent emergency braking function has activated, it is then disabled, as the vehicle is assumed to be damaged. After the vehicle has been repaired, the intelligent emergency braking function can be reenabled using Land Rover approved diagnostic equipment.

The intelligent emergency braking function operates at vehicle speeds down to zero, and will function even when forward alert and adaptive speed control are switched off.

If the intelligent emergency braking feature is disabled for any reason, a related message is displayed in the Instrument Cluster (IC) message center.

ENGINE DRAG-TORQUE CONTROL (EDC)

Engine Drag-Torque Control (EDC) prevents wheel slip caused by any of the following:

- A sudden decrease in engine torque when the accelerator is suddenly released.

- The sudden engagement of the clutch after a downshift on manual transmission vehicles.

- A downshift using the paddle switch on automatic transmission vehicles.

HILL DESCENT CONTROL (HDC)

Hill Descent Control (HDC) uses engine braking and brake intervention to control the vehicle speed and acceleration during low speed off-road descents and in low grip on-road conditions. Generally, equal pressure is applied to all four brakes, but pressure to individual brakes may be modified by the Anti-lock Brake System (ABS) and HDC functions to retain vehicle stability. Selection of the HDC function is controlled by the HDC switch (or the dual purpose HDC/ATPC switch) located on the floor console. HDC operates at vehicle speeds up to 50km/h (31mph).

WARNING:

Incorrect use of the HDC function may compromise the stability of the vehicle, resulting in a dangerous and uncontrolled hill descent.

Pressing the clutch pedal and/or driving with the transmission in neutral while HDC is active, will prevent engine braking from assisting the vehicle. The brakes will overheat and induce the HDC fade out strategy. In this condition there will be no control over the vehicle during a descent.

NOTE:

With the HDC function selected, HDC is operative even when the clutch pedal is pressed or the transmission is in neutral. It is not recommended to drive the vehicle further than is absolutely necessary with HDC selected, and the clutch pedal pressed or the transmission in neutral.

On manual transmission vehicles, HDC may be used in first, second and reverse gears only. Once the vehicle is moving, the clutch pedal is to be fully released. The vehicle is not recommended to be driven with HDC active and the transmission in neutral.

On automatic transmission vehicles, HDC may be used in D (drive), R (reverse) and gears 1,2 and 3 in sport mode. When in D, the Transmission Control Module (TCM) will automatically select the most appropriate gear. It is not recommended to drive the vehicle with HDC active and the transmission in N (neutral).

HDC can be selected at any speed, but will only be enabled at speeds below 50km/h (31mph).

When HDC is selected:

- At speeds up to 50km/h (31mph), the HDC active indicator is permanently illuminated if a valid gear is selected.

- At speeds above 50km/h (31mph), the HDC active indicator flashes and a message advising that the speed is too high is displayed in the message center.

When HDC is enabled, the driver decides upon a target speed. Initially a default target speed is adopted, then, in any valid gear, the driver can adjust this target speed using the speed control switches. The new selected target speed will be indicated to the driver on the HDC display in the Instrument Cluster (IC) message center. The HDC function then compares this target speed with the actual vehicle speed. The ABS control module then operates the Hydraulic Control Unit (HCU) in the active braking mode as required, to achieve and maintain the target speed. Operation of the vehicle stop lamps during HDC is controlled by the Central Junction Box (CJB).

Applying the foot brake during active braking may result in a pulse being felt through the brake pedal.

The target speed can be varied between minimum and maximum values for each gear and transmission range, depending on driver inputs through the speed control switches. If no speed control switches are pressed the ABS control module adopts the appropriate default target speed:

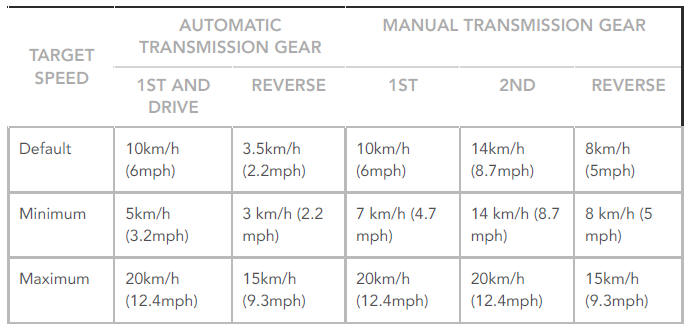

Hill Descent Control (HDC) Target Speeds

The target speed is varied between the minimum and maximum values using the speed control '+' and '-' switches. If the driver brakes during HDC control, the driver generated brake pressure supplements the deceleration and the vehicle will slow further. When the brake pedal is released the previously adopted target speed will be used once again. When the driver presses the accelerator pedal the vehicle will accelerate normally and HDC will not intervene; as soon as the driver releases the accelerator pedal the pre-selected target speed will be maintained once more.

During changes of target speed, the ABS control module limits vehicle deceleration and acceleration to -0.5m/s2 (-1.64ft/s2) and +0.5m/s2 (+1.64ft/s2) respectively.

To provide a safe transition from active braking to brakes off, the ABS control module invokes a fade out strategy that gradually releases the braking effort during active braking. The fade out strategy occurs if any of the following conditions is detected during active braking:

- HDC is selected off using the HDC switch.

- Failure of a component used by HDC, but not critical to the fade out function

- Brake overheat.

If fade out is invoked because of HDC de-selection or component failure, the HDC function is cancelled by the ABS control module. If fade out is invoked because of brake overheat, the HDC function remains in standby and resumes operation when the brakes have cooled.

The fade out strategy increases the target speed at a constant acceleration rate of 0.5m/s2 (1.64ft/s2), until the maximum target speed is reached, or until no active braking is required for 0.5 second. If the accelerator pedal is positioned within the range that influences target speed, the acceleration rate is increased to 1.0m/s2 (3.3ft/s2).

When fade out is invoked because of component failure, a warning chime is sounded and the HDC active indicator is extinguished. A message advising of the fault is displayed in the message center.

When fade out is invoked because of brake overheat, a message advising that HDC is temporarily unavailable is displayed. At the end of fade out, the HDC active indicator flashes. The flashing active indicator lamp and displayed message continue while HDC remains selected, until the brakes have cooled.

To monitor for brake overheat, the ABS control module monitors the amount of braking activity and, from this, estimates the temperature of each brake. If the estimated temperature of any brake exceeds a preset limit, the ABS control module invokes the fade out strategy. After a fade out cycle, the HDC function is re-enabled when the ABS control module estimates that all of the brake temperatures are at less than 64% of the preset temperature limit.

ALL TERRAIN PROGRESS CONTROL (ATPC)

The All Terrain Progress Control (ATPC) can help the driver to maneuver on slippery surfaces. The system operates in either a forward or a reverse direction at low speeds, for example, pulling away from standstill, ascending or descending an incline, and driving on unstable/slippery driving surfaces.

ATPC is selectable via the HDC/ATPC switch (dual purpose switch). One press = ATPC, two press = HDC if second press is within 4 seconds, three press = off. If 4 seconds or more elapse after first press then second press = off.

Once selected ATPC will be in descent control (DC) mode, controlling vehicle speed but not providing any acceleration or positive engine torque, until the driver selects D or R on the Transmission Control Switch (TCS), and then activates full function by pressing the speed control SET '+' or '-' switch on the right steering wheel switchpack.

Once full function has been activated the driver can adjust the target speed from a minimum of 1.8 km/h to a maximum of 30 km/h either via the speed control switches or by adjusting the vehicle speed with accelerator or brake pedal and then pressing SET '+' again (in the same was as one would for standard speed control). A press and hold of the speed control '+' or '-' switch allows the car to accelerate or decelerate at pre-determined rates depending on the current Terrain Response program to allow smooth launch control without wheel spin or faster changes in the drivers desired set speed.

Individual presses of the '+' and '-' switches change the target speed up or down by pre-determined amounts. From 1.8 km/h up to circa 5 km/h each press = 0.5 km/h, between 5 km/h and 10 km/h each press = 1 km/h and between 10 km/h and 30 km/h each press = 2 km/h.

Once a set speed has been selected ATPC will endeavor to maintain that target speed over any terrain that lies in front (or behind if R is selected) of the vehicle. The ABS control module controls the amount of brake torque and engine torque at all times to maintain the vehicle speed selected, overcome obstacles, negotiate any inclines or descents and ensure as smooth an operation as possible. The set speed can be adjusted at any time. The resume 'RES' switch can be used to re-adopt the previous set speed after driver braking.

The display on the Instrument Cluster (IC) provides the driver with the information they require on engaging the function, and a visual graphic shows ATPC activation, including the current vehicle speed, the range of selectable target speeds and the target speed the driver has selected.

ATPC works in conjunction with Hill Start Assist (HSA), launches on inclines are therefore part of the ATPC benefits.

ATPC has different calibrations in each Terrain Response program that have been developed to optimise performance on that particular surface.

GRADIENT RELEASE CONTROL

Gradient release control is an automatic system which is always available when Hill Descent Control (HDC) or All Terrain Progress Control (ATPC) is selected.

If the vehicle is brought to a standstill on a slope using the foot brake, gradient release control will become active (except in the terrain response, sand program).

When descending a hill, a brake hold and gradual release is employed to provide a smooth transition into HDC or ATPC. Gradient release control operates in forward and reverse gears and requires no driver intervention.

ACTIVATION OF STOP LAMPS

Operation of the vehicle stop lamps during Hill Descent Control (HDC) or All Terrain Progress Control (ATPC) is controlled by the Central Junction Box (CJB). The Anti-lock Brake System (ABS) control module monitors the brake system hydraulic pressure and requests the CJB, via the High Speed (HS) Controller Area Network (CAN) chassis bus, to energize the stop lamps during active braking.

A pressure threshold and time filter prevents the stop lamps from flickering while HDC or ATPC is braking.

AUTO STOP/START VEHICLES

Activation of Hill Descent Control (HDC) or All Terrain Progress Control (ATPC) will deactivate the auto stop/start system. If HDC or ATPC is activated while the engine is shutdown in a auto stop/start cycle, the engine will automatically restart. However, if the auto stop/start system cannot detect the driver, for example either the driver safety belt or the driver door is unlatched, the engine will not restart. The auto stop/start system will then request the driver to depress the clutch, to restart the engine, by displaying an appropriate message in the message center. The driver must respond to this request within a limited time period, otherwise a conventional engine restart using the engine START/STOP switch will be required.

HILL START ASSIST (HSA)

Regardless of Hill Descent Control (HDC) or All Terrain Progress Control (ATPC) selection, the automatic hill start assist function will aid smooth transition from foot brake release to moving away, on all ascents above a 5% gradient. It does this by holding driver generated brake pressure for a short period of time (2-3 seconds) and then balancing brake torque with the propulsion torque generated when the accelerator pedal is applied, to ensure the vehicle does not roll backwards.

YAW STABILITY CONTROL (YSC)

The Yaw Stability Control (YSC) function uses the brakes and the engine to attempt to restore vehicle stability if the vehicle is forced into a harsh maneuver that risks it tipping over.

The Anti-lock Brake System (ABS) control module monitors driver inputs and vehicle behavior using various powertrain signals and inputs of wheel speed, steering angle, yaw rate, roll rate and lateral acceleration. These inputs are compared with modeled behavior and, if the vehicle behavior reaches a given risk level, the ABS control module cuts the engine power, or brakes one or more wheels sufficiently to allow the vehicle to regain stability and help the driver remain in control.

While the ignition is energized, YSC is permanently enabled even if the Dynamic Stability Control (DSC) function is selected off.

TERRAIN RESPONSE

The Terrain Response function integrates the ABS and other vehicle system control modules to assist the vehicle when driving off-road or during difficult surface conditions. Terrain response is activated when a terrain response special program is selected.

When a terrain response special program is activated, the ABS control module, along with other vehicle system control modules, will operate in accordance with programmed software maps. The software maps allow the ABS system to function with a threshold that will assist the selected terrain response special program.

For additional information, refer to: Ride and Handling Optimization (204-06 Ride and Handling Optimization, Description and Operation).

TRAILER BRAKE CONTROL MODULE

When the trailer electrical socket is connected, the trailer brake control function operates automatically to enhance the existing Dynamic Stability Control (DSC) and Terrain Response functions of the vehicle when towing.

The system detects sway movements caused by trailer oscillations at speeds in excess of 50km/h (31mph) and acts to eliminate them. It does this through braking and engine management. Braking the vehicle asymmetrically counterbalances the sway movement, thereby slowing the vehicle and eliminating the oscillations. Engine management adapts engine torque output to support the braking management in stabilizing the vehicle and trailer.

Typical conditions when sway can occur include:

- Changing highway lanes.

- Traversing a lengthy bend.

- Acceleration.

- Braking.

- Incorrectly laden trailers.

The capability of trailer brake control module is to respond early to the beginning of trailer-sway makes the system almost unnoticeable under normal driving conditions and keeps the vehicle and trailer under safe control. Trailer brake control module requires no input from the driver and operates up to the maximum vehicle speed.

Trailer brake control module will not operate while DSC is switched off.

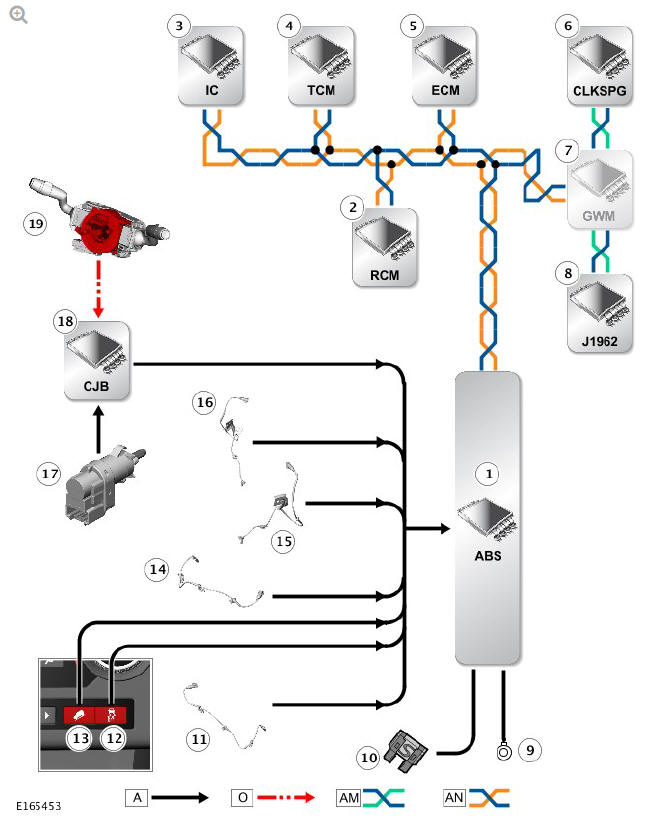

CONTROL DIAGRAM

A = HARDWIRED; O = LOCAL INTERCONNECT NETWORK (LIN) BUS; AM = HIGH SPEED (HS) CONTROLLER AREA NETWORK (CAN) CHASSIS BUS; AN = HS CAN POWERTRAIN BUS.

- Anti-lock Brake System (ABS) control module

- Restraints Control Module (RCM)

- Instrument Cluster (IC)

- Transmission Control Module (TCM)

- Engine Control Module (ECM)

- Clockspring (CLKSPG)

- Gateway Module (GWM)

- Diagnostic Connector (J1962)

- Ground

- Power supply

- Rear left wheel speed sensor

- Dynamic Stability Control (DSC) switch

- Hill Descent Control (HDC) switch

- Rear right wheel speed sensor

- Front right wheel speed sensor

- Front left wheel speed sensor

- Brake pedal switch

- Central Junction Box (CJB)

- CLKSPG